Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

Choosing the right air compressor for your impact wrench is essential for getting your work done properly. This guide will help you understand the basics of air compressors and impact wrenches, and show you how to pick the best size for your needs. We’ll cover important factors to consider, give recommendations for different situations, and answer common questions.

Understanding Air Compressors and Impact Wrenches

What Is an Air Compressor?

An air compressor is a machine that takes in air from the environment, compresses it to increase its pressure, and stores it in a tank. This compressed air can then be used to power various pneumatic tools, including impact wrenches.

How Does an Impact Wrench Work?

An impact wrench is a powerful tool used to tighten or loosen nuts and bolts. It works by applying a strong rotational force (torque) in short, intense bursts. These bursts are created by a hammering mechanism inside the tool, which is powered by compressed air from an air compressor.

Why Matching Air Compressor Size Matters

Using the right size air compressor is crucial for several reasons:

Performance: If the compressor is too small, your impact wrench won’t have enough air to work properly. This can lead to poor performance and longer job times.

Efficiency: A well-matched compressor will run more efficiently, saving you money on energy costs.

Tool lifespan: Using an undersized compressor can put extra strain on your impact wrench, potentially shortening its lifespan.

Cost-effectiveness: Buying a compressor that’s too large for your needs is a waste of money and space.

Key Factors in Determining Air Compressor Size

1. Cubic Feet Per Minute (CFM)

CFM is the most important factor to consider when choosing an air compressor for your impact wrench.

What Is CFM?

CFM measures the volume of air that a compressor can deliver in one minute. It tells you how much air your compressor can supply to your impact wrench.

CFM Requirements for Impact Wrenches

Different sizes of impact wrenches require different amounts of air:

- Small impact wrenches (1/4″ to 3/8″ drive): 2-4 CFM

- Medium impact wrenches (1/2″ drive): 4-5 CFM

- Large impact wrenches (3/4″ to 1″ drive): 5-8 CFM

Always check the specific CFM requirements for your impact wrench. This information is usually found in the tool’s manual or on the manufacturer’s website.

2. Pounds Per Square Inch (PSI)

PSI measures the pressure of the compressed air.

Why PSI Is Important

Most impact wrenches need between 90 and 100 PSI to work effectively. If the PSI is too low, your impact wrench won’t have enough power to do its job properly.

PSI Requirements for Impact Wrenches

- Light-duty impact wrenches: 90 PSI

- Medium-duty impact wrenches: 90-100 PSI

- Heavy-duty impact wrenches: 100-120 PSI

Fortunately, most air compressors can easily reach 90 PSI, which is sufficient for most impact wrenches.

Read More In-Details: How Much Psi for Impact Wrench

3. Tank Size

The size of the air compressor’s tank affects how long you can use your impact wrench before the compressor needs to refill the tank.

How Tank Size Affects Performance

A larger tank allows you to use your impact wrench for longer periods without interruption. However, larger tanks also make the compressor heavier and less portable.

Recommended Tank Sizes

- For quick, occasional use: 2-6 gallon tank

- For regular DIY projects: 8-20 gallon tank

- For professional use: 30-60 gallon tank or larger

Matching Air Compressor Size to Impact Wrench Needs

For Small Impact Wrenches (1/4″ to 3/8″ drive)

These impact wrenches are suitable for light work such as assembling furniture or working on small engines.

Recommended Air Compressor Specs

- CFM: 2-4 CFM at 90 PSI

- Tank Size: 2-6 gallons

- Example: A 6-gallon pancake compressor with 2.6 CFM at 90 PSI would be suitable

Our Choice: Metabo HPT 6 Gallon Air Compressor. The most reliable air compressor for impact wrench with 200 PSI Max and 4 CFM.

For Medium Impact Wrenches (1/2″ drive)

These are commonly used for automotive repair and home improvement projects.

Suitable Air Compressor Size

- CFM: 4-5 CFM at 90 PSI

- Tank Size: 8-20 gallons

- Example: A 20-gallon vertical compressor with 5.0 CFM at 90 PSI would be a good match

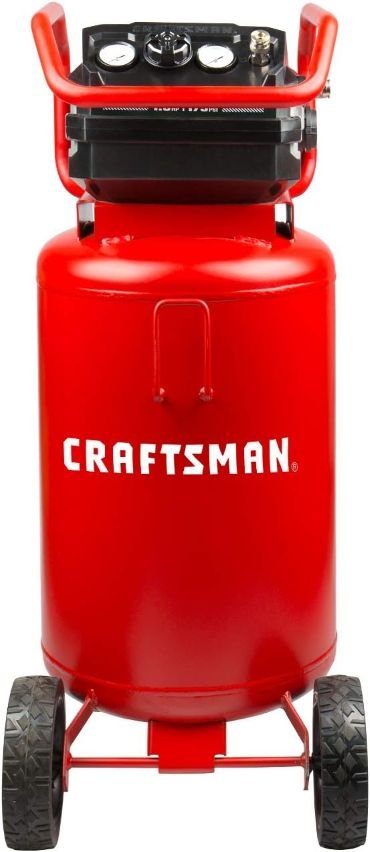

Our Choice: Craftsman 20 gal Vertical Portable Air Compressor 175 psi 1.8 HP

For Large Impact Wrenches (3/4″ to 1″ drive)

These heavy-duty impact wrenches are typically used in professional auto shops or construction sites.

Air Compressor Requirements

- CFM: 5-8 CFM at 90 PSI

- Tank Size: 30-60 gallons or larger

- Example: A 60-gallon Single-Stage Compressor with 11.3 CFM at 90 PSI would handle most large impact wrenches.

Our Choice: Ingersoll Rand SS3L3 3hp 60 Gallon. (100% continuous duty cycle and single-Stage)

Additional Considerations for Choosing An Air Compressor

Duty Cycle

The duty cycle of an air compressor refers to how long it can run before needing to cool down. For regular use, look for a compressor with a duty cycle of 50% or higher.

Portability

If you need to move your compressor around, consider its weight and whether it has wheels. Pancake and hot dog compressors are typically more portable, while larger tank sizes are usually stationary.

Future Tool Needs

Think about other air tools you might want to use in the future. Buying a slightly larger compressor now could save you money in the long run if you plan to expand your tool collection.

Power Source

Electric compressors are better suited for indoor use and are generally quieter. Gas-powered compressors are more suitable for outdoor use where electricity may not be available.

Recommended Air Compressor Sizes for Common Scenarios

DIY/Occasional Use

For home projects or occasional use:

- CFM: 2-5 CFM at 90 PSI

- Tank Size: 6-20 gallons

- Example: Porter Cable 6-gallon pancake compressor with 2.6 SCFM at 90 PSI

This setup is perfect for occasional use of small to medium impact wrenches, as well as other light-duty air tools like nail guns or staplers.

Professional Automotive Work

For a small to medium-sized auto repair shop:

- CFM: 5-7 CFM at 90 PSI

- Tank Size: 20-60 gallons

- Example: Klutch 20-Gallon Air Compressor with 4.2 SCFM at 90 PSI

This configuration can handle most automotive tasks, including using impact wrenches, air ratchets, and spray guns.

Industrial Applications

For heavy-duty industrial work:

- CFM: 10+ CFM at 90 PSI

- Tank Size: 60-80 gallons or larger

- Example: VEVOR 80-gallon two-stage compressor with 15.5 SCFM at 90 PSI

This powerful setup can run multiple large impact wrenches simultaneously, as well as other high-demand air tools commonly used in industrial settings.

Tips for Choosing the Right Air Compressor

Read Manufacturer Specifications Carefully

Always check the CFM rating at 90 PSI. Some manufacturers list CFM at lower PSI levels, which can be misleading. Make sure you’re comparing apples to apples when looking at different models.

Consider Brand Reputation and Reviews

Look at what other users say about the compressor. Pay attention to comments about reliability, noise levels, and overall performance. A well-regarded brand with positive reviews is often worth the investment.

Budget for Long-Term Needs

It’s often better to buy a slightly larger compressor than you currently need. This gives you room to grow and use more powerful tools in the future without having to upgrade your compressor.

Noise Levels

If noise is a concern, look for compressors with lower decibel ratings. Oil-lubricated compressors are typically quieter than oil-free models.

Warranty and Customer Support

A good warranty can save you money on repairs down the line. Also, check if the manufacturer has reliable customer support in case you need help or have questions.

Frequently Asked Questions

Can I use a pancake compressor for an impact wrench?

Yes, you can use a pancake compressor for small to medium impact wrenches. However, they typically have small tanks and lower CFM ratings, so they’re best suited for short, occasional use.

How do I calculate the CFM needs for my impact wrench?

Check your tool’s manual or specifications for its CFM requirements. If you can’t find this information, a good rule of thumb is to add 50% to the tool’s CFM rating to ensure you have enough air supply.

Is it better to get a larger air compressor than I currently need?

Often, yes. A larger compressor gives you more flexibility to use different tools and work for longer periods. However, balance this with your budget and space constraints.

What’s the difference between oil-lubricated and oil-free air compressors?

Oil-lubricated compressors typically last longer and run quieter, but they require regular oil changes. Oil-free compressors need less maintenance and can be used in environments where oil contamination is a concern, such as painting or food processing.

How does altitude affect air compressor performance?

At higher altitudes, air is thinner, which can reduce a compressor’s output. As a general rule, for every 1,000 feet above sea level, compressor output decreases by about 3%. If you’re working at high altitudes, you may need a larger compressor to compensate for this loss in performance.

Final Thoughts

Picking the right size air compressor for your impact wrench is key to getting your work done efficiently and effectively. Remember these important points:

- Match the CFM rating of the compressor to your impact wrench’s needs.

- Ensure the compressor can deliver at least 90 PSI.

- Choose a tank size that fits your usage pattern.

- Consider other air tools you might want to use in the future.

- Think about factors like portability, noise levels, and maintenance requirements.

By keeping these factors in mind, you’ll be able to select an air compressor that works well with your impact wrench and meets your specific needs. This will help you work more efficiently and get your jobs done right.

Remember, the best air compressor for you depends on your specific needs and working conditions. Take the time to assess your requirements and compare different models before making a decision. With the right air compressor, your impact wrench will perform at its best, making your work easier and more productive.