Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

To check a generator exciter, start by inspecting the wiring and connections. Then, measure the voltage output and ensure proper functioning.

Generators are critical devices, especially during power outages. The exciter is an essential part that ensures the generator produces electricity efficiently. Regular checks can prevent malfunctions and extend the life of your generator. Understanding how to check the exciter can save time and money.

It can also keep your generator running smoothly when needed. This guide will help you understand the steps to inspect and maintain the exciter. By following these instructions, you can ensure your generator remains reliable and effective. Let’s dive into the process to keep your generator in top condition.

Safety Precautions

Ensure the generator is off and disconnected from power before checking the exciter. Inspect wiring and connections for any signs of damage. Use a multimeter to test voltage and resistance levels.

When checking a generator exciter, safety should always be your top priority. Overlooking safety can lead to serious injuries or even fatalities. Follow these safety precautions to protect yourself and your colleagues.

Personal Protective Equipment

Ensure you are wearing the appropriate Personal Protective Equipment (PPE). This includes safety glasses, gloves, and protective footwear. PPE acts as your first line of defense against potential hazards.

Wear a long-sleeved shirt and long pants to protect your skin. Make sure your clothing is not loose to avoid getting caught in moving parts. Helmets are also essential, especially in construction or industrial areas.

I remember a colleague who ignored wearing gloves while working on a generator. He ended up with severe burns. Don’t make the same mistake.

Work Area Safety

Keep your work area clean and organized. A cluttered workspace can lead to accidents. Remove any unnecessary tools or materials.

Ensure the generator is turned off and properly grounded before you start. This reduces the risk of electric shock. Always double-check with a voltmeter.

Place warning signs around the work area to alert others. This ensures no one accidentally turns on the generator or enters the danger zone.

Have you ever tripped over a misplaced tool? It’s not just annoying—it’s dangerous. Keep everything in its place to avoid unnecessary risks.

By following these safety precautions, you not only protect yourself but also create a safer environment for everyone involved. Safety should never be an afterthought. What safety measures do you take when working with generators?

Credit: generators.tpub.com

Required Tools And Equipment

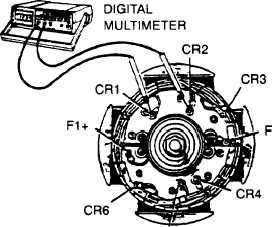

When checking a generator exciter, having the right tools and equipment can make the process smoother and more effective. Accurate measurements and assessments are crucial for ensuring your generator is functioning optimally. Here, we’ll dive into the essential tools you need: a multimeter and an insulation tester.

Multimeter

A multimeter is an indispensable tool for checking a generator exciter. This versatile device measures voltage, current, and resistance, which are key indicators of your generator’s health.

When I first started checking generators, I underestimated the importance of a good multimeter. A friend recommended investing in a high-quality one, and it made a world of difference.

Ensure your multimeter has a wide range and is easy to use. Look for models with clear digital displays and robust build quality. Brands like Fluke or Klein Tools are reliable choices.

Have you ever struggled with unclear readings? A precise multimeter eliminates this issue, giving you confidence in your assessments.

Insulation Tester

An insulation tester is another critical piece of equipment. This tool checks the insulation resistance of electrical components, preventing potential faults and ensuring safety.

I remember once overlooking this tool and facing unexpected downtime. An insulation tester helps you avoid such setbacks by identifying weak points early.

Choose an insulation tester with a range suitable for your generator’s specifications. Megger and Hioki are reputable brands that offer reliable performance.

Ever wondered why insulation testing is crucial? It ensures your generator’s components are protected against electrical leaks and shorts, prolonging its lifespan.

By equipping yourself with these tools, you can efficiently check your generator exciter, ensuring it runs smoothly and reliably. Do you have these tools in your toolkit?

Initial Inspection

Start the initial inspection by examining the generator exciter for any visible damages. Check all connections and wires for proper attachment. Ensure there are no loose or corroded components.

Ensuring your generator exciter is in top shape starts with a thorough initial inspection. This step is crucial for identifying any obvious issues before they become major problems. Here’s how you can get started with a proper initial inspection.

Visual Inspection

Begin with a careful visual inspection of the generator exciter. Look for any visible signs of wear and tear, such as frayed wires or loose components. These could indicate potential issues that need immediate attention.

Dust and debris can also accumulate over time, affecting performance. Make sure the exciter and its surrounding area are clean. You can use a soft brush or a can of compressed air for this task.

Check for any discoloration or burnt marks on the exciter. These are often signs of overheating and could indicate underlying electrical issues.

Checking Connections

Next, move on to checking the connections. Ensure that all wires and cables are securely connected. Loose connections can lead to poor performance or even damage the exciter.

Use a multimeter to verify the continuity of the electrical connections. This tool will help you determine if there are any breaks or faults in the wiring.

While you’re at it, check for any signs of corrosion on the connectors. Corrosion can impede the flow of electricity and should be cleaned immediately. A simple mixture of baking soda and water can be used to clean corroded areas.

Engage With Your Findings

Have you noticed any issues during your inspection? Address them immediately. Small problems can escalate quickly if left unchecked.

Remember, a well-maintained generator exciter ensures the reliability of your generator. Taking the time to perform these inspections can save you from unexpected breakdowns and costly repairs.

What did you discover during your initial inspection? Share your findings and insights in the comments below. Your experiences can help others maintain their equipment more effectively.

Electrical Testing

Performing electrical testing on a generator exciter is crucial for ensuring its proper function and longevity. This process involves measuring voltage and current to detect any anomalies that could lead to failures. Let’s dive into the specifics of these tests.

Voltage Measurement

To measure the voltage of your generator exciter, you’ll need a reliable voltmeter. Start by turning off the generator and ensuring it’s in a safe condition. Connect the voltmeter probes to the exciter terminals.

Switch on the generator and take note of the voltage reading. Compare this reading with the manufacturer’s recommended levels. Consistent readings within the specified range indicate a healthy exciter.

Have you ever noticed a sudden drop in voltage? This could signal an issue with the exciter winding or a connection problem. Inconsistent voltage can lead to equipment damage or operational failure.

Current Measurement

Current measurement requires an ammeter. Like voltage testing, ensure the generator is turned off before connecting the ammeter in series with the exciter circuit. Safety first!

Turn on the generator and observe the current reading. It should align with the manufacturer’s specifications. Variations might indicate problems such as short circuits or overloads.

Imagine detecting a higher current than expected. This could mean excessive load or a fault in the exciter. Addressing this early can save costly repairs and downtime.

When was the last time you checked your generator exciter? Regular electrical testing can prevent unexpected failures and extend the life of your equipment. So, don’t wait for a breakdown to take action.

Exciter Resistance Check

Checking the generator exciter’s resistance is crucial for its optimal performance. This process ensures that your generator works efficiently and reliably. It also helps to identify any potential issues early, preventing costly repairs. There are two main types of resistance checks: winding resistance and insulation resistance.

Winding Resistance

Measure the winding resistance to ensure the exciter’s windings are intact. Use a digital multimeter set to the ohm setting. Place the meter probes on the exciter terminals. Record the readings displayed on the meter. Compare these readings with the manufacturer’s specifications. A significant deviation indicates a problem with the windings.

Insulation Resistance

Check insulation resistance to prevent electrical faults. Use an insulation resistance tester for this process. Connect one lead to the exciter terminal and the other to the ground. Activate the tester and note the resistance value. Ensure the measured value meets the required standards. Low insulation resistance suggests damaged insulation, needing immediate attention.

Credit: www.youtube.com

Operational Testing

Operational testing is a critical step in ensuring your generator exciter is functioning correctly. This process helps you identify any issues before they become significant problems. By conducting both no-load and load tests, you can verify the exciter’s performance under different conditions.

No-load Test

The no-load test checks the generator exciter without connecting it to any load. This means the generator runs without powering any devices. Here’s how you can perform it:

- Start your generator and allow it to reach its operating speed.

- Measure the voltage output at the exciter terminals.

- Compare the measured voltage with the manufacturer’s specifications.

- If the voltage is within the acceptable range, your exciter is likely functioning well under no-load conditions.

If the voltage is outside the specified range, you may need to adjust the excitation system. It’s a good idea to consult the generator’s manual for specific instructions. Always ensure your safety by following the proper procedures and using the right tools.

Load Test

Next, conduct a load test to check the exciter’s performance under actual working conditions. This test ensures the exciter can handle the electrical load it’s designed to support. Follow these steps:

- Connect a load to the generator. This could be a resistive load bank or actual equipment that the generator will power.

- Gradually increase the load and monitor the generator’s output voltage and frequency.

- Ensure the voltage remains stable as the load increases.

- Observe any fluctuations or irregularities in voltage and frequency.

During the load test, it’s crucial to watch for any signs of the exciter struggling. For example, if the voltage drops significantly as you increase the load, this could indicate an issue. Make sure your generator can sustain the load for a reasonable period without any performance degradation.

Have you ever noticed your generator acting up during a power outage? Imagine the peace of mind knowing your exciter is in top shape. By regularly performing these tests, you can avoid unexpected failures and ensure your generator is always ready to go.

What steps will you take today to check your generator exciter? Regular maintenance and testing are key to reliable performance. Don’t wait for a failure to happen. Be proactive and keep your equipment in excellent condition.

Troubleshooting Common Issues

When checking your generator exciter, you may encounter a range of issues that can affect performance. Addressing these problems promptly ensures your generator operates efficiently. Let’s look at common issues and how to troubleshoot them.

Low Voltage Output

Low voltage output is a frequent problem in generators. First, ensure that all connections are secure and free of corrosion. Loose or dirty connections can cause voltage drops.

Next, check the exciter field resistance using a multimeter. If resistance is too high or too low, it might indicate a faulty exciter coil. Replacing the coil can often resolve the issue.

Sometimes, the voltage regulator might be the culprit. Ensure it’s functioning correctly and replace it if necessary. A faulty regulator can’t maintain the proper voltage levels.

Excessive Vibration

Excessive vibration can damage your generator over time. Start by inspecting the mounting bolts. Loose bolts can cause the generator to vibrate excessively.

Check the alignment of the exciter and generator. Misalignment can lead to imbalance and vibration. Adjusting the alignment can reduce or eliminate these vibrations.

Another common cause is worn bearings. Inspect the bearings for wear and replace them if needed. Proper lubrication also helps in reducing friction and vibration.

Regular maintenance and inspections can prevent many of these issues. Have you faced any unexpected problems with your generator? Share your experiences and solutions in the comments below!

Credit: merequipment.com

Frequently Asked Questions

How To Manually Excite A Generator?

To manually excite a generator, connect a DC power source to the field winding terminals. Gradually increase the voltage until the generator starts producing electricity. Ensure all connections are secure and monitor the output closely.

How Do You Test An Alternator Exciter?

To test an alternator exciter, use a multimeter to measure the exciter voltage and check for proper output. Ensure connections are secure.

What Happens When A Generator Loses Excitation?

A generator losing excitation can lead to voltage collapse. It may cause instability, overheating, and potential damage. Regular maintenance and monitoring are crucial to prevent such issues.

How Does The Exciter On A Generator Work?

The exciter on a generator provides the necessary field current to the rotor, creating a magnetic field. This magnetic field induces voltage in the stator windings, generating electricity.

Final Words

Regular checks ensure your generator exciter works efficiently. Follow the steps mentioned for accurate results. These steps are simple and easy to perform. Regular maintenance prevents costly repairs. Keep your generator in top shape and avoid unexpected failures. Protect your investment with routine inspections.

Reliable performance starts with proper care. Ensure safety by checking all connections. A well-maintained generator lasts longer and performs better. Be proactive and check your generator exciter regularly for peace of mind.