Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

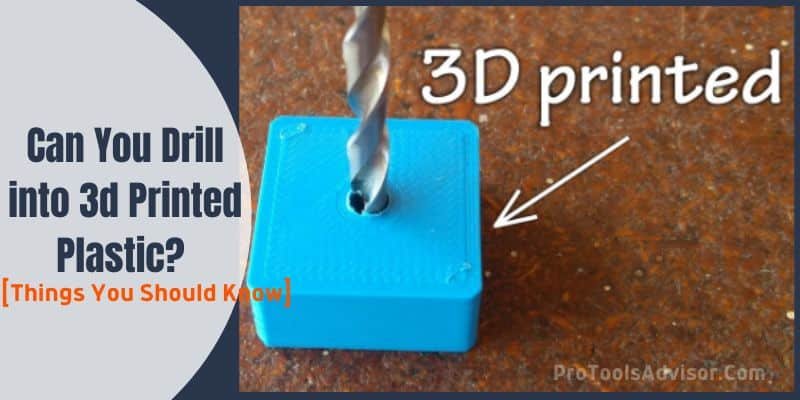

Yes, you can certainly drill into 3d printed plastics. But there are some catches. 3d printed plastic is not solid throughout the entire part. You can crack or melt it if you are not careful enough while drilling.

Talking about drilling, questions may arise such as why you need to drill into 3d printed plastic if it is delicate. Well, you might want to drill if you forget to design a hole unless you want to reprint everything from scratch. Additionally, you may want to raise the diameter of the hole to put some shaft into it.

With proper instructions and guidelines, you can drill into 3d printed plastic without causing any damage or harm. Let’s learn how you should do this in the right way!

What is 3d Printed Plastic?

There is a plastic layer over 3d printed materials. This layer can be either of two printing filaments named ABS and PLA.

PLA stands for Poly Lactic Acid and is one of the most widespread 3d printing materials. Because of its simple functions PLA works for a wide number of 3d printing applications. The melting point is low which makes it an easy material to use. PLA has a great surface quality and decent strength but they are not suitable for parts which will be exposed to the elements for a long period of time.

ABS filament is also a very popular 3d printing material. ABS is more sensitive to the temperature changes in the environment. ABS needs to cool slowly. It will crack the layer lines along with the print if it gets cooling too rapidly. ABS print is robust and can tolerate more heat, pressure, and stress than PLA. This makes it a great choice for applications that have wear and tear issues. Both PLA and ABS have their fair share of pros and cons and should be chosen according to the use cases.

Why Drilling into 3d Printed Plastic Can Be Necessary

Whether you have a PLA filament or ABS filament as your 3d printing materials, it is necessary to do some post-management work. Drilling is a part of post-management and is important for the following reasons –

- To correct any printing mistakes occurred during the production period.

- To change the external shapes or functionalities for any real-life purposes.

- To increase the strength and the robustness of the printed plastic.

How To Drill into 3d Printed Plastic?

You need to be careful while drilling a hole into a 3d printed plastic material as any misjudgment can make the whole part obsolete. Don’t drill a hole in a 3d printed part by following the traditional style like the wood drilling.

The standard practice to follow while drilling is to make a pilot hole first. This will improve the drilling accuracy and help make it precise. Consider the following–

- Print the hole at a slightly smaller size to avoid the risk of making an unwanted, bigger hole. Try to use a sharp drill bit.

- Drill horizontally to separate the layers. Try to bend the drill bit at a 45 angle with the z-direction. Drilling in the z-direction has a better performance rate.

- Drill at a lower speed. Fast speed and rotation will heat up the plastic because of more fractions with the part. This heat will soften up the part and you most likely won’t get a clean round cut. This issue happens more with PLA filament as they have a low tolerance to bends and tears.

- Put the drill bit at the slowest speed while you are entering or exiting the hole.

- Try to put some infill on the print. It’s especially useful if you know you will need to make a hole in the part but are not sure about the exact location.

- Best case scenario is to know where to put the hole even before the printing. Though things change and you have to put your best effort accordingly.

Tips to do drilling safely and perfectly

Drilling is a machinery work and it needs some precautions to follow –

- Stray plastic parts can randomly fly around the places while drilling the material and may get into your eyes. Wear safety sunglasses to avoid this risk.

- Wear protective glasses to eliminate the risk of burning out your hands by the heat generated from high-speed drilling.

- Have patience and give it some time while drilling. Don’t try to act and do the work too fast.

Which drill bits to use for 3d printed plastics?

You can use regular wood drill bits to drill a hole into 3d printing material. It works okay and is pretty common to find. Sharp drill bits work significantly better with plastic materials. That’s why using special plastic drill bits is a better choice. These plastic cutting drills have sharper points than a regular drill. They have a low chance of damaging the plastic parts and have a high-performance rate. These plastic cutting drill bits are also available in most of the hardware shops and machinery stores.

See This Video Tutorial

Final Words

Drilling into the 3d printed plastic is possible with some necessary cautions. 3d printed objects get drilled quite commonly and it’s certainly achievable. All you need to do is follow some instructions which are specifically applicable to drill into 3d printed plastic objects. Follow the guidelines that are described above and you are good to go.