Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

Generators are vital for providing power during outages. But how are they kept cool?

There are two main methods to cool a generator. Understanding these cooling methods is essential for efficient generator operation. Proper cooling prevents overheating and extends the life of the generator. The two common cooling methods are air cooling and liquid cooling.

Each has its own set of benefits and drawbacks. Learning about these methods helps in choosing the right generator for your needs. In this blog post, we will explore both cooling methods in detail. By the end, you’ll have a clear understanding of how each method works and which might be best for your situation.

Air Cooling

When it comes to cooling a generator, one common method is air cooling. This technique uses air to keep the generator at a safe operating temperature. Understanding how air cooling works, along with its advantages and disadvantages, can help you make an informed decision about whether it’s the right cooling method for your generator.

Mechanism

The air cooling method works by using fans or blowers to move air over the generator’s components. The moving air absorbs heat from the generator, carrying it away and thereby cooling the device. This process often involves a radiator to help dissipate the heat more effectively.

For instance, think about how a fan in your room cools you down by moving air over your skin. Similarly, the fans in an air-cooled generator work to keep the internal parts from overheating.

Advantages

Air cooling has several benefits. First, it is generally simpler and less expensive to implement than other cooling methods. There are fewer components involved, making it easier to maintain.

Another advantage is that air-cooled systems tend to be more robust. Because they lack liquid coolant, there is no risk of coolant leaks or the need to monitor coolant levels.

Additionally, air cooling is often sufficient for smaller generators. If you have a small to medium-sized generator, air cooling can be an effective and straightforward solution.

Disadvantages

However, air cooling does have some downsides. The primary disadvantage is that it is less effective for larger generators. Larger machines produce more heat, and air alone may not be enough to keep them cool.

Moreover, air-cooled systems can be noisy. The fans required to move enough air to cool the generator can produce a significant amount of noise, which might be a consideration in noise-sensitive environments.

Lastly, the efficiency of air cooling can be impacted by the surrounding environment. In hot and humid conditions, the air may not be able to absorb and carry away as much heat, reducing the cooling effectiveness.

Have you ever wondered how well an air-cooled system would work in your specific situation? Consider the size of your generator and your environmental conditions to make the best choice for your needs.

Credit: grillpartsreplacement.com

Liquid Cooling

Generators are essential for providing power during outages or in remote locations. But have you ever wondered how they stay cool while running? One effective method is liquid cooling. It’s fascinating how this method works to keep your generator at optimal performance levels. Let’s dive into the details.

Mechanism

Liquid cooling works by circulating coolant liquid around the engine. This liquid absorbs the heat generated and transfers it to a radiator or heat exchanger. The coolant is then cooled down and recirculated.

Think of it like how your car’s radiator works. The key is the continuous loop that keeps the engine from overheating. It’s a dynamic process that ensures your generator runs smoothly.

Advantages

Liquid cooling has several benefits:

- Efficiency: It is very effective at removing heat. This ensures your generator can handle high loads without overheating.

- Quiet Operation: Liquid-cooled generators tend to be quieter than their air-cooled counterparts. This is great for residential areas.

- Longevity: By maintaining optimal temperature, liquid cooling can help extend the lifespan of your generator. This means fewer maintenance costs in the long run.

Imagine having a generator that runs quietly in the background, allowing you to focus on your tasks. That’s the advantage of liquid cooling.

Disadvantages

However, there are some downsides:

- Complexity: Liquid cooling systems are more complex. They require regular maintenance to check for leaks and coolant levels.

- Cost: They are generally more expensive to buy and maintain. The initial investment can be higher compared to air-cooled systems.

- Potential for Leaks: There is always a risk of coolant leaks. This can lead to engine damage if not addressed promptly.

Think about the last time you had to deal with a car radiator leak. The same principles apply here. It requires attention and care.

So, what’s your take? Is liquid cooling worth the investment for your needs? Weighing the pros and cons can help you make an informed decision. After all, keeping your generator cool is crucial for its performance and durability.

Comparing Air And Liquid Cooling

Generators can be cooled using air or liquid methods. Air cooling uses fans, while liquid cooling uses coolant fluids. Both methods help maintain the generator’s temperature.

Generators need effective cooling to operate properly. There are two main cooling methods: air and liquid. Each method has its own benefits and challenges. Understanding these can help you choose the best option for your needs.Efficiency

Air cooling uses fans to move air over the generator. This method is simple but less efficient. It relies on ambient air temperature, which can vary. Hot environments may decrease cooling efficiency. Liquid cooling uses coolant to transfer heat away. This method is more efficient. The coolant absorbs heat and moves it to a radiator. This keeps the generator at a stable temperature. Liquid cooling works well in all climates.Cost

Air cooling systems are cheaper to install. They have fewer parts and are less complex. This reduces initial costs. Maintenance costs are also lower since there are no fluids to manage. Liquid cooling systems are more expensive. They require more components, such as radiators and pumps. These increase the initial installation cost. Maintenance can also be higher due to the need to check and replace coolant.Maintenance

Air cooling systems need less maintenance. There are no fluids to monitor or replace. Regular cleaning of fans and vents is usually enough. This makes them easier to care for over time. Liquid cooling systems need more upkeep. Coolant levels must be checked regularly. The system may need flushing to remove debris. Radiators and pumps also require occasional inspection. This means more time and cost for maintenance. By comparing air and liquid cooling, you can see their key differences. Each method has unique benefits and challenges. Your choice depends on your specific needs and conditions. “`

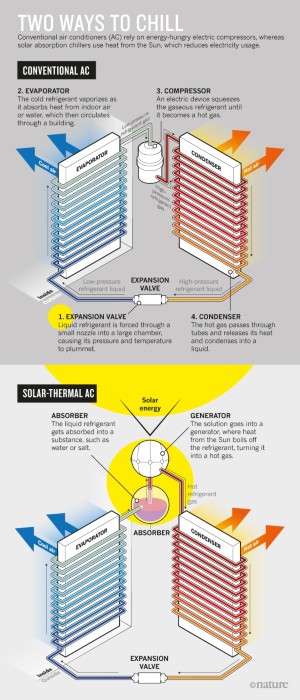

Credit: www.nature.com

Applications Of Air Cooling

Air cooling is a common method for keeping generators at safe temperatures. This technique uses ambient air to remove heat from the generator. It’s efficient for small and portable generators. These generators often operate in environments where compact size and simplicity are crucial.

Small Generators

Small generators benefit greatly from air cooling. These generators are often used in residential settings. They power essential appliances during outages. Air cooling makes them more affordable and easier to maintain. The design is simple, leading to fewer mechanical issues. They can fit into tight spaces without the need for extensive ventilation systems.

Portable Generators

Portable generators are another application where air cooling excels. These generators are used for outdoor activities and emergency situations. Air cooling keeps them lightweight and easy to transport. The system requires no extra fluids, reducing the risk of leaks. This feature is ideal for camping trips and construction sites. Users can rely on them without worrying about overheating.

Applications Of Liquid Cooling

Liquid cooling is an essential method for maintaining the efficiency of generators. This technique involves using a liquid medium to absorb and dissipate heat generated by the machine. Let’s explore how liquid cooling is applied in different contexts.

Large Generators

Large generators are often used in power plants and other significant facilities. These machines generate substantial amounts of heat during operation. Liquid cooling is crucial in these scenarios to ensure continuous performance and prevent overheating.

Imagine a power plant running 24/7. The generator’s temperature can skyrocket. Liquid cooling helps manage this by circulating coolant through the generator, absorbing excess heat and maintaining optimal temperature.

This method is efficient and reliable. It allows large generators to operate smoothly without interruptions. Have you ever wondered what keeps your city lights on? Liquid cooling in large generators plays a key role.

Industrial Use

In industrial settings, generators are often used to power heavy machinery. These environments demand robust and consistent performance. Liquid cooling is applied to ensure the generators can handle long working hours without overheating.

Picture a factory floor with machines running continuously. The generators powering these machines need to stay cool to avoid any downtime. Liquid cooling circulates coolant through the generator, maintaining a steady temperature and ensuring uninterrupted operation.

This cooling method also extends the lifespan of the generators. By preventing overheating, liquid cooling reduces wear and tear. Isn’t it fascinating how a simple coolant can enhance the efficiency of industrial operations?

What do you think? Could liquid cooling be the future of generator maintenance in various applications? Your thoughts and experiences can shape the discussion. Feel free to share!

Credit: www.amazon.com

Choosing The Right Cooling Method

Choosing the right cooling method for a generator is crucial. It impacts performance and longevity. There are two main cooling methods: air cooling and liquid cooling. Each has its own benefits and drawbacks. Understanding these can help in making an informed decision.

Factors To Consider

Before choosing a cooling method, consider the generator’s size. Larger generators often need more efficient cooling. The environment also matters. Hot climates may require stronger cooling methods. The generator’s workload is another factor. A heavily used generator generates more heat.

Maintenance is also important. Air-cooled systems are simpler and need less maintenance. Liquid-cooled systems, while efficient, need regular checks. Budget constraints can also influence the decision. Air cooling is usually cheaper than liquid cooling.

Expert Recommendations

Experts suggest air cooling for small to medium generators. These generators do not generate extreme heat. Air cooling is cost-effective and simpler to maintain. For larger generators, experts recommend liquid cooling. These systems handle higher heat levels. Liquid cooling is also more efficient for continuous use.

Consulting a professional can provide more personalized advice. They can assess specific needs and recommend the best option. Taking expert advice can prevent future issues and ensure the generator runs smoothly.

Future Trends In Generator Cooling

The future of generator cooling looks promising with advancements in technology. New methods aim to make cooling more efficient and eco-friendly. Let’s explore some of the key trends shaping the future of generator cooling.

Technological Advances

Modern cooling systems use advanced materials. These materials conduct heat better, making cooling faster. Smart sensors play a key role. They monitor temperature and adjust cooling automatically. This ensures optimal performance and prevents overheating.

Another exciting development is the use of liquid cooling. Liquid cooling systems are more efficient than air cooling. They can remove more heat and keep generators running smoothly. This trend is gaining popularity in high-performance generators.

Environmental Impact

There is a growing focus on reducing the environmental impact of generator cooling. Green cooling technologies are being developed. These systems use eco-friendly coolants that have a lower carbon footprint.

Renewable energy sources are also being integrated into cooling systems. Solar-powered fans and pumps are being used. This reduces the reliance on fossil fuels and promotes sustainability. These trends not only help the environment but also lower operating costs.

Frequently Asked Questions

What Are Two Ways A Generator Can Be Cooled?

Generators can be cooled using air or liquid cooling systems. Air cooling uses fans to circulate air, while liquid cooling uses coolants.

What Are Two Ways To Cool Down A Generator?

Two ways to cool down a generator are air cooling and liquid cooling. Air cooling uses fans, while liquid cooling circulates coolant.

What Are The Cooling Methods Of Generators?

Generators use various cooling methods such as air cooling, hydrogen cooling, and water cooling. Air cooling uses fans, hydrogen cooling offers high efficiency, and water cooling provides effective heat dissipation.

What Are The 2 Types Of Generator?

There are two types of generators: portable and standby. Portable generators are versatile and used for temporary power. Standby generators automatically provide backup power during outages.

Conclusion

Generators need effective cooling to work well. Two common methods are air and liquid cooling. Air cooling uses fans to cool the generator. Liquid cooling uses water or coolant to lower the temperature. Choosing the right method depends on generator size and use.

Proper cooling extends generator life and ensures safe operation. Always follow the manufacturer’s guidelines for best results. Ensure regular maintenance to avoid overheating issues. Understanding these cooling methods helps maintain a reliable generator.