Disclosure: This post contains affiliate links and I will be compensated if you make a purchase after clicking through my links. Learn More

To bypass the oil pressure switch on a generator, locate the switch and disconnect its wiring. This action will disable the safety feature.

Generators play a vital role in providing backup power during outages. Occasionally, the oil pressure switch may malfunction, causing the generator to shut down unnecessarily. Bypassing this switch can be a temporary solution to keep the generator running. It’s crucial to understand the risks involved, as bypassing the switch can lead to engine damage if oil pressure drops.

Always monitor oil levels and pressures closely after performing this bypass. Consulting the generator’s manual and seeking professional advice ensures a safer and more effective solution. Regular maintenance can prevent such issues from occurring in the first place.

Tools And Materials

To bypass the oil pressure switch on a generator, you will need specific tools and materials. This section covers everything required for the task. Having the right items ensures the process is smooth and safe.

Required Tools

- Screwdrivers – You will need both flathead and Phillips screwdrivers.

- Wrenches – A set of adjustable wrenches is ideal.

- Multimeter – Essential for checking electrical connections.

- Wire Strippers – Necessary for preparing the wires.

- Electrical Tape – For securing the connections.

Necessary Materials

- Bypass Wire – A piece of wire to create the bypass.

- Connectors – To join the wires securely.

- Heat Shrink Tubing – Provides insulation for the wire connections.

- Replacement Switch – In case you need to replace the oil pressure switch later.

Below is a table summarizing the tools and materials for easy reference:

| Tools | Materials |

|---|---|

| Screwdrivers | Bypass Wire |

| Wrenches | Connectors |

| Multimeter | Heat Shrink Tubing |

| Wire Strippers | Replacement Switch |

| Electrical Tape |

Locate The Oil Pressure Switch

Bypassing the oil pressure switch on a generator requires precision. Locating the oil pressure switch is the first crucial step. This guide helps you find and identify the switch efficiently.

Finding The Switch

Finding the oil pressure switch on your generator is straightforward. Usually, it is near the engine block. The switch is typically a small, round component.

Check the generator’s manual for exact location details. If the manual is unavailable, look for a small metal or plastic component with wires attached. The switch often has a single wire or a pair of wires connected to it.

Identifying The Wires

Once you locate the switch, the next step is identifying the wires. Usually, there are two wires connected to the switch. One wire is the input wire and the other is the output wire.

Using a multimeter, you can test the wires. Set the multimeter to continuity mode. Touch the probes to the wire ends and check the reading. If you get a beep or continuity signal, you have identified the wires correctly.

| Step | Action | Details |

|---|---|---|

| 1 | Locate the switch | Near the engine block, small round component |

| 2 | Check manual | Refer for exact location |

| 3 | Identify wires | Use a multimeter for continuity |

By following these steps, you can easily locate and identify the oil pressure switch and its wires on your generator. This ensures a proper bypass process.

Preparing The Generator

Before bypassing the oil pressure switch on your generator, proper preparation is crucial. This ensures the process is smooth and safe. Below are essential steps to follow.

Ensuring Safety

Safety should always come first. Wear protective gloves and goggles. This helps avoid injuries during the process.

Make sure the generator is in a well-ventilated area. This prevents inhaling harmful fumes.

Keep a fire extinguisher nearby. This is essential in case of emergencies.

Disconnecting Power

Begin by disconnecting the power source. Unplug the generator from any connected appliances.

Next, remove the spark plug. This ensures the generator does not start accidentally.

Use a wrench to disconnect the battery terminals. Always remove the negative terminal first.

Label the wires to avoid confusion later. This makes reassembly easier and safer.

Ensure all power sources are disconnected before proceeding. Double-check to ensure safety.

Bypassing The Switch

Bypassing the oil pressure switch on a generator can solve many problems. This process is simple and helps keep your generator running smoothly. Follow these steps to bypass the switch safely.

Disconnecting The Switch

First, locate the oil pressure switch on your generator. The switch is usually near the engine. Ensure the generator is off and cooled down before starting. This step is crucial for safety.

Next, disconnect the wires from the oil pressure switch. Use a wrench to loosen the switch if needed. Carefully remove the switch from the generator.

Connecting Wires

Now, connect the wires together to bypass the switch. Use a wire connector or electrical tape. Ensure the connection is tight and secure.

After connecting the wires, test the generator. Start it up and check for any issues. If everything works fine, the bypass is successful.

Always remember safety first. Keep your hands and tools dry. Wear protective gear like gloves and goggles.

Testing The Generator

Testing your generator is crucial after bypassing the oil pressure switch. This ensures it operates smoothly and safely. Follow these steps to confirm your generator is functioning correctly.

Initial Startup

Begin by placing your generator on a flat, stable surface. Connect the necessary cables securely. Double-check all connections to avoid any hazards. Make sure the fuel tank is full.

- Turn the fuel valve to the ON position.

- Set the choke to the START position.

- Pull the starter cord firmly until the engine starts.

Observe the generator during this initial phase. Listen for any unusual noises. If the generator struggles to start, recheck all connections.

Monitoring Performance

Once your generator is running, it’s important to monitor its performance. This helps identify any potential issues early on.

| Parameter | Optimal Range |

|---|---|

| Voltage Output | 110-120V (AC) |

| Frequency | 60 Hz |

| Noise Level | Below 70 dB |

Use a voltmeter to check the voltage output. Ensure it stays within the optimal range. Listen for the noise level; it should not exceed 70 dB. Check the frequency using a frequency meter.

Keep an eye on the fuel level. Refill as needed to prevent interruption.

- Check oil level regularly.

- Inspect for any fuel leaks.

- Monitor the exhaust for unusual smoke.

By following these steps, you can ensure your generator runs efficiently and safely.

Troubleshooting

Generators are essential during power outages. Sometimes, the oil pressure switch may cause problems. This section will help you troubleshoot common issues and find possible solutions.

Common Issues

- Generator fails to start

- Oil pressure warning light stays on

- Generator shuts down unexpectedly

Possible Solutions

Here are steps to bypass the oil pressure switch:

- Locate the oil pressure switch near the engine.

- Disconnect the wire connected to the switch.

- Use a jumper wire to bypass the switch.

- Reconnect the generator and test it.

Bypassing the oil pressure switch can solve many issues. Always check the generator’s oil level first.

Table Of Common Solutions

| Issue | Solution |

|---|---|

| Fails to start | Check oil level and bypass switch |

| Warning light on | Inspect connections and bypass switch |

| Shuts down | Bypass switch and test |

Important: Always ensure safety first. Follow manufacturer guidelines.

Final Steps

Completing the process of bypassing the oil pressure switch on your generator requires careful attention. The final steps are crucial to ensure the generator operates safely and efficiently.

Reassembling Components

Once the bypass is complete, reassemble all disconnected components. Ensure all wires and connectors are secure. Use the appropriate tools to tighten any loose screws or bolts.

Refer to the generator’s manual for specific reassembly instructions. This will help avoid any mistakes. Double-check all connections before moving forward.

Final Safety Checks

Perform final safety checks to ensure everything is in order. Verify that the generator is in a safe location. Ensure there are no flammable materials nearby.

- Inspect all connections

- Check for any loose wires

- Ensure the generator is grounded properly

Turn on the generator and observe its operation. Look for any unusual sounds or behaviors. If everything seems fine, your bypass is successful.

| Steps | Actions |

|---|---|

| Reassemble components | Secure all wires and connectors |

| Perform safety checks | Inspect connections and grounding |

| Test generator | Observe for any issues |

By following these steps, you can ensure your generator works safely after bypassing the oil pressure switch.

Frequently Asked Questions

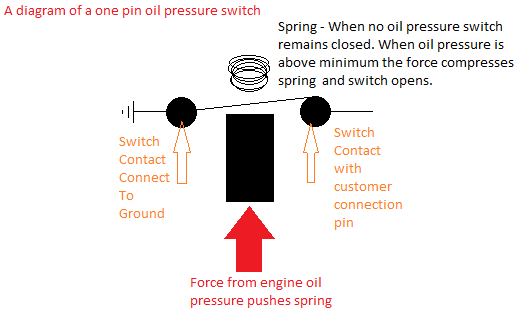

What Is An Oil Pressure Switch?

An oil pressure switch is a safety device in your generator. It keeps track of oil pressure while the engine runs. If oil pressure drops too low, it shuts off the generator to protect the engine from damage. Think of it as your engine’s guard that stops costly repairs.

Why Bypass An Oil Pressure Switch?

People bypass oil switches mainly to test if the switch is faulty or in emergencies. But remember – this is very risky. If your generator keeps shutting off, first check your oil level and quality. A bypass should be your last option and only for testing.

How To Safely Bypass The Switch?

For testing only: turn off the generator, find the oil pressure switch (check your manual), unplug its wires, and join them together. This lets you check if the switch is the problem. Always reconnect it after testing. If unsure, ask a repair professional.

Is Bypassing Safe For Long-term Use?

No, never bypass the oil switch for long periods. This is like removing your engine’s safety guard. Low oil pressure can destroy your generator’s engine in minutes. Always fix the real problem – whether it’s bad oil, a faulty switch, or other issues.

Final Thoughts

Bypassing the oil pressure switch on a generator requires caution and expertise. Always prioritize safety while performing this task. Understanding the process can save time and reduce downtime. Ensure you follow proper guidelines to maintain your generator’s efficiency. Knowledge and careful execution are key to successful bypassing.